Please select your location & language for the best website experience

As our world moves towards a digital transformation, automation is a crucial tool for a thriving business. 51% of our recent webinar attendees said inefficient manual processes is their biggest challenge. By automating processes, companies can make their workflows faster and more efficient, enabling them to do more with less.

Your barcode labeling environment is no exception. With automated label printing, you can create a labeling process that is faster, more efficient, and has less room for errors. This blog will go over how to automate your label printing and how TEKLYNX can help in providing solutions.

Request Print Automation Consult

The main goal of print automation is to minimize touch points within the labeling process. Humans are prone to error, so minimizing human interaction will lead to fewer mistakes and a smoother workflow. By automating data input within your label design software through features such as database connections, forms, PortWatch, or RESTful API integration, you can ensure that your labels are populated with the correct data. This provides peace of mind regarding the accuracy of your labels.

A complete label print automation solution integrates your label design software and printing technologies with your existing business system, ERP, WMS, or custom homegrown system. Within a fraction of a second, your print automation software can trigger a print job using the data from your business system. It can automatically populate your labels and print to an unlimited number of printers.

Read our print automation case studies to learn how Flex-Strut increased their print speed by 100% and how TaylorMade increased its labeling accuracy to 99%.

Creating a more streamlined process for your label printing users can be achieved through features in your label design software. Easily populate variable data with database connections, provide a more user-friendly label printing interface with forms, and remove the need for manual data entry by taking advantage of PortWatch.

With print automation there is no need to upload templates to separate stations. Instead of creating static labels, leverage label templates that can easily populate variable data with your print automation software.

Your business system already contains all the necessary data you need to populate your labels, so why not take advantage of this? Eliminating manual data entry ensures the correct information is on your labels by integrating your labeling system with your business system, such as Oracle, SAP, NetSuite, Microsoft Dynamics, Global Shop Solutions, and many more.

Use print automation to control all your print jobs from a centralized location. Easily manage multiple workstations from the comfort of your desk.

Now that you understand the need for automated label printing, let’s discuss the methods by which you can achieve automated label printing.

The more data fields that need to be manually populated, the more room for error. Database connections are a feature in TEKLYNX label design software that enable label templates to pull variable data in from an existing database. This feature allows you to enter or select one key data element (such as the part number or order number), and all other data is automatically populated on the label.

Forms within TEKLYNX label design software allow you to customize your label printing experience. With the help of Form Editor and Form Designer, you can create your ideal printing process.

Form Editor is a simple way to organize print time data and enforce data entry. Form Editor gives you the ability to add drop-down menus, incrementing value fields, sliders, date pickers, radio buttons, and more, ensuring your labels are formatted correctly 100% of the time.

Form Designer separates the label design process from the label printing process. Print users simply find the label they want to print, select the number of copies needed, and click print. You can do all this without even having to open the label design software. Separating the label design process from the print process saves time by eliminating steps for print users.

Entering data onto a label is time consuming and poses the risk of inaccurate data being printed. With PortWatch, you can completely remove the need for manual data entry. PortWatch is a powerful feature within CODESOFT that allows you to collect data from a port like a scanner, keyboard, or a scale. The data is then printed on to your label with no data entry involved.

Enabling RESTful API allows companies to automate labeling workflows and integrate labeling processes with their existing business system. This reduces the time and resources required for labeling and creates greater workflow efficiency. RESTful API ensures that labeling data is accurate and consistent across all systems, reducing the risk of errors. RESTful API is often used for building web services that allow different software systems to bi-directionally communicate with each other over the internet. By integrating print automation with RESTful API it allows for bi-directional communication. Now when you're printing out of your business system, you will receive immediate feedback about that print job and whether it passed or completed, or any errors that may have occurred.

Dot Foods is the largest food industry redistributor in North America. They have been helping companies move food products more efficiently and cost-effectively from manufacturer to distributor since 1960. Headquartered in Illinois, Dot Foods serves over 1,100 food manufacturers across North America. As Dot Foods grew, their labeling needs did as well and TEKLYNX was there to help.

Dot Foods had to acquire a new labeling software to support their labeling needs, create modern pallet labels and other custom labels for their customers. They needed someone who could provide technical support for their 14 distribution centers in the United States, Canada, and Mexico.

Dot Foods collaborated with the TEKLYNX Enterprise Team to determine that the advanced barcode label creation software, CODESOFT, and print automation solution, SENTINEL, would be the right fit. With their newly implemented SENTINEL automated label printing solution, Dot Foods maintained their HA environment and gained reliability. Their new labeling software is in all 14 distribution centers across North America.

CODESOFT enterprise-level label design software, coupled with built-in sample APIs enables automated label printing directly to local workstations with advanced label creation and robust database connections. CODESOFT + API is great for helping companies who want to automate multiple workstations and have multiple non-networked printers.

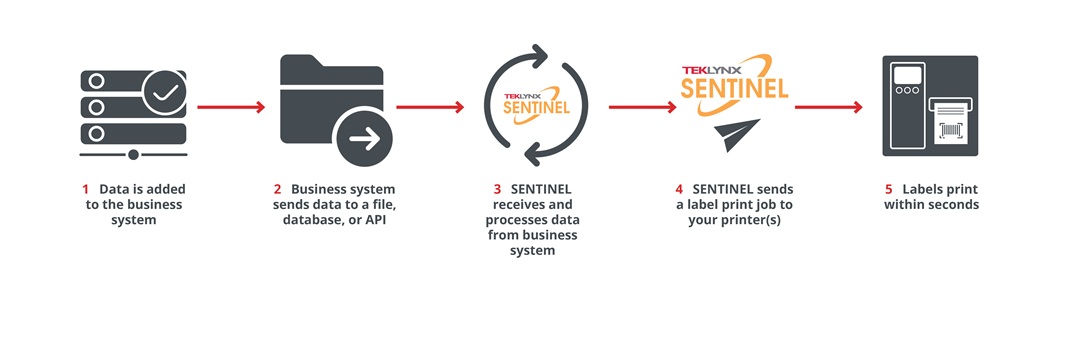

SENTINEL, print automation solution facilitates automatic label printing from ERP, WMS or other business systems. With the ability to print to unlimited printers and integrate with RESTful API, this solution is designed for larger environments, offering ease of use and reliability.

How it works:

The TEKLYNX Software Development Kit (SDK) helps businesses of all sizes expand their label printing automation offerings. This solution complements label printing automation products, SENTINEL, and CODESOFT with APIs to help your company's labeling process. The TEKLYNX SDK is tailor-made for software developers and solutions providers to embed high-quality label design and printing within a WMS, MES, ERP system, LIMS, or custom-built application.

The TEKLYNX SDK provides easy integration of label design and printing into existing software applications for a streamlined and efficient user experience. Equipped with .NET wrapper and RESTful API, companies benefit from well-supported and updated libraries, cutting development time and providing a smooth integration process. The lightweight nature of the TEKLYNX SDK means it can be installed and configured without a lot of technical requirements. This reduces the time and effort required to set up the barcode label printing functionality, enabling faster implementation and quicker time-to-value.

To learn more about TEKLYNX label printing automation solutions, watch our print automation webinar, Modern Approaches to Automating Label Printing: 3 Powerful Methods.

If you are interested in automating your label printing process to save time, create efficiencies, and reduce errors, request a free demo of SENTINEL. Interested in exploring our label automation solutions further? Request a consult with one of our labeling experts today!

Request Print Automation Consult

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

Software system integration is a key tool used by businesses to enhance operations. Instead of each software application existing in its own silo, system integration allows separate applications to talk to each other. Integrating disjointed software solutions is commonly viewed as a challenge, but at TEKLYNX, we offer four main ways to integrate labeling systems with your existing technology stack.

READ MORE

RESTful API, or simply REST API, is often used for building web services that allow different software systems to bi-directionally communicate with each other over the internet. REST API has been used by manufacturers for a variety of purposes, including streamlining their labeling processes. Read our blog to learn how it's evolving labeling processes for manufacturers.

READ MORE

No matter what industry you’re in, proving Return on Investment (ROI) is always a top priority. Within this blog you will learn how to prove ROI with your ERP labeling integration.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. All Rights Reserved.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.