Please select your location & language for the best website experience

National Manufacturing Day, also known as MFG Day, takes place on the first Friday in October. It is a day when manufacturers have the biggest opportunity to inspire and promote manufacturing to the next generation, jumpstarting their careers, and highlighting what manufacturing is all about. TEKLYNX recognizes and appreciates all our manufacturing customers.

Labeling Solutions for Manufacturing

This blog goes over the importance of National Manufacturing Day, the technology and careers behind manufacturing, how TEKLYNX barcode labeling software fits into the manufacturing industry, and future manufacturing trends.

Manufacturing Day is not just about promoting manufacturing but creating visibility for the industry and working to inspire the next generation to consider pursuing manufacturing as a future career. Manufacturers throughout the United States opened their doors on October 4, 2024, to offer tours and teach young individuals how the fourth industrial revolution, or Industry 4.0, is changing our world in a good way.

Not only is manufacturing one of the largest sources of commercial innovation, but it fuels the economy by creating millions of jobs. NAM.org stated that in the month of August 2022, manufacturing alone employed over 12 million workers, the most since November 2008. This sets up the manufacturing industry for a successful future.

The manufacturing industry had more than 2.6 million job openings nationally in 2022, showing little signs of a workforce shortage slowing down. With more job openings there is a need to promote jobs within the industry and increase process efficiencies with technology to do more with less.

Technology is a driving force for economies around the globe. New advanced manufacturing technologies are bringing more careers to the table and requiring skilled individuals to fill those positions. Manufacturers are looking for workers from a wide variety of educational backgrounds, these experts are needed for areas beyond the factory floor; they will be high-paying jobs such as Manufacturing Directors, Analysts, Engineers, Operators, Technicians, Labeling Experts, and Specialists. These positions are hands-on and require creativity, innovation, and problem-solving skills.

Some may think with automation growing in many industries, there is no longer a need for real human skills; reality is quite the opposite. Manufacturers appreciate all the help they can get from individuals. Automating manual processes helps eliminate waste, due to errors, saves money, and frees up employees' time to work on other value-added projects throughout the workday. Automating your manual tasks is critical to Lean Manufacturing: a production process focused on minimizing waste within manufacturing. Start implementing more sustainable practices into your labeling process, since the future of manufacturing will be put under more pressure for Green Factories.

Barcode labeling plays an important role in manufacturing processes and product traceability. It allows manufacturers to track and trace procedures throughout the supply chain, helps industries stay on top of regulatory compliance guidelines, and reduces the impact in the case of a product recall. TEKLYNX works to provide barcode labeling software that grows with you and creates trusted partnerships with our manufacturing customers.

See how TEKLYNX helped some of our manufacturing customers accomplish goals such as increasing flexibility, and reducing development time, improving print speed, and reducing labeling errors in these three case studies:

The future of manufacturing is centered around automation, smart factories, IIoT (Industrial Internet of Things), using the cloud, sustainable manufacturing, and new careers.

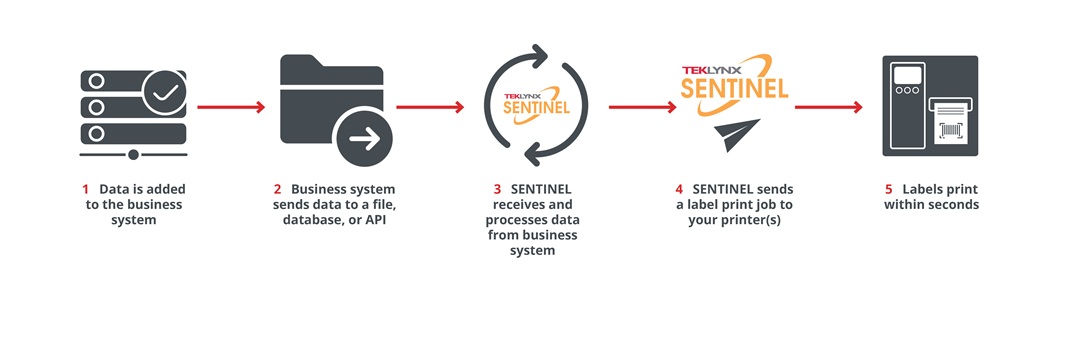

As previously mentioned, automation is one of the trends taking over many industries, especially manufacturing. Using machines to reduce the work for humans will create more time for workers to focus on other important tasks as new technologies rise. Automate your label printing processes using SENTINEL Print Automation Software.

Smart factories and the IIoT work together to drive digitization. A smart factory is a highly digitized and connected manufacturing environment that shares data through machines or devices. In order to have smart factory solutions that work effectively, manufacturing companies must rely on IIoT. The IIoT is an extension of the Internet of Things, and it relies on applications with sensors to improve manufacturing processes. Smart factories powered by the IIoT have the potential to create better productivity and reliability in operations.

Cloud computing plays a big role in smart factories as it helps store all the data the smart factories collect in a database using an ERP system or WMS. An increasing number of manufacturers are implementing cloud technologies as it creates a more reliable and scalable business, reduces errors, and helps centralize operations. Cloud-enabled label printing is becoming more popular in labeling environments, especially in manufacturing. You can print labels from anywhere, at any time using a browser-based label printing interface, which helps companies reduce costs and streamline processes.

Modern manufacturing is a cleaner, leaner, and greener industry that continues to implement sustainable practices in manufacturing. Sustainable manufacturing uses economically-sound processes that reduce negative environmental impacts while still saving energy and natural resources. Sustainable manufacturing increases consumer demands because consumers are getting smarter in their purchasing process and doing research for sustainable products coming from sustainable companies.

Storebrands.com states, “Globally sustainability is rated as an important purchase factor for 60% of consumers with 61% in the U.S. saying sustainability is important when buying a new product, while 34% of those surveyed said they would be willing to pay more for sustainable products or services”. Not only is sustainable manufacturing helping the environment, but it provides more safety for products, employees, and the community.

Reducing waste is a top priority for manufacturers, and they can do this by implementing a labeling solution that follows lean labeling strategies. Linerless labeling is a type of lean labeling practice in manufacturing that reduces the use of paper since the barcode labels are made without a liner. Businesses are starting to turn to linerless labeling as the best option for sustainable printing. Sustainability is important to incorporate into business operations as it reduces costs with simple packaging, reduces energy consumption, and helps protect the environment.

With the future trends in manufacturing and current labor shortages, the need for more employees is rising. Manufacturers are not only looking for hands-on experts to join the industry but will seek skilled and data-focused talent to manage state-of-the-art equipment, build and manage workflows, manage software programs, and more. Manufacturing employees work in all types of industries like pharmaceutical, engineering, food manufacturing and clothing manufacturing.

Manufacturing and barcode labeling are the backbones of the supply chain and help make the world go around. Almost everything we see, touch, or feel is manufactured in some way, shape, or form. Whether the items are created by the manufacturer or passed through the facility, they are part of our everyday lives, which is why manufacturing careers are critical to maintaining a strong economy.

Not only does TEKLYNX provide barcode labeling software to many manufacturers, but we create a long-lasting and trusted partnership with all our customers. We take this day to show our appreciation and spread awareness about the industry, the careers behind it, and the people who help make it happen.

At TEKLYNX, our barcode label software solutions help make supply chains work, but it’s the people behind our products that make them work better. Our customer support team constantly works hard to make sure our manufacturing customers are always taken care of. If you are looking for a new barcode labeling software provider or want to know more about TEKLYNX, get in touch with a TEKLYNX labeling expert today.

Take a look at the MFG.day website to see where manufacturers near you are opening their doors on National Manufacturing Day.

Doug Niemeyer is the President & General Manager at TEKLYNX Americas. He leverages his 25+ years of sales & marketing experience in technology and leadership to help grow the business. His passion for leadership, insatiable curiosity, and competitive spirit help to drive success, encourage progress and development while ensuring teams hold positive customer experiences in the highest regard, all with the purpose of helping companies barcode better. When he is not working you can find him in a gym, on a field or golf course playing or coaching.

Business agility and technology adoption is even more critical for organizations to operate through the turbulence from an unusually quick economic rebound and to compete in the next growth period. This blog will explain four trends in the manufacturing industry and how labeling will support those trends through 2022 and beyond so you can set your company up for success.

READ MORE

Manufacturers worldwide face numerous challenges in labeling, from meeting customer demands and regulatory compliance to addressing growing sustainability concerns and inefficient labeling processes. This blog will showcase how three TEKLYNX customers overcame labeling challenges in manufacturing with print automation software.

READ MORE

Seamlessly print your labels to multiple locations with cloud label printing options. This blog will go over four unique ways to leverage the cloud for label printing, answers to commonly asked questions about each option, and how using the cloud can benefit your labeling environment.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. All Rights Reserved.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.