En iyi web sitesi deneyimi için lütfen konumunuzu ve dilinizi seçin

GS1 US® is a not-for-profit information standards organization. GS1 Standards are the most widely used supply chain standards in the world and support many regulatory compliance requirements across a variety of industries. Founded in 1973 and based in Ewing, New Jersey, GS1 US administers the Universal Product Code (UPC) barcode, as well as other information standards and data carriers. In this blog, Cait Platt at GS1 US will cover some of the basic barcode placement guidelines for labels.

The first step is to license your GTIN with GS1. Your next step to getting your product into the supply chain is placing your barcode on your actual product. Getting your product to go “beep” at checkout requires your packaging to follow a few simple rules about color, placement, and size.

Fun fact: On June 26, 1974, in a Marsh supermarket located in Ohio, a pack of Wrigley’s gum became the first product in the world to be scanned with a barcode.

GET HELP WITH GS1 LABEL DESIGN

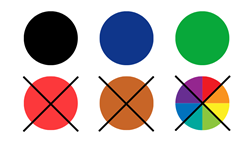

Colors of the barcode backgrounds impact the ability to scan the barcode properly; therefore, you need to consider the placement of the barcode as that may influence color selections. The most common barcode is the iconic black bars and white background (spaces and quiet zones) for a reason, it’s easy for retail checkout to read. However, these colors don’t work for every product on the market, so there are guidelines to follow when choosing the colors of your barcode.

Colors of the barcode backgrounds impact the ability to scan the barcode properly; therefore, you need to consider the placement of the barcode as that may influence color selections. The most common barcode is the iconic black bars and white background (spaces and quiet zones) for a reason, it’s easy for retail checkout to read. However, these colors don’t work for every product on the market, so there are guidelines to follow when choosing the colors of your barcode.

Looking for tips on designing your labels? Check out 6 ways to design your barcode labels better.

Where you place your barcode on the packaging affects both the products’ movement throughout the supply chain and the end user’s experience. For barcodes scanned at checkout, you’ll want to consider things like packaging shape. Barcodes can be placed horizontally, with the bars running like a picket fence, or vertically, with the bars running like a ladder, it’s up to you to decide which works best depending on the space on the item.

For example, boxes with flat surfaces can use a horizontally placed barcode but when your product is cylindrical with a small radius, like a tube of lipstick, a vertically placed barcode would be best. Barcodes need to be placed on smooth, continuous surfaces so make sure to steer clear of bumpy packaging or getting too close to the edge of your packaging.

Due to the uniqueness of a GS1 barcode, the bars and background are designed with a fixed relationship between the length and width. As you adjust one measurement, an equal adjustment must be made of the other to maintain the readability. Things like truncating the barcode (removing portions) or printing graphics or text too close to the edge of the barcode (in the quiet zones) can create an incorrect scan. Create your barcode art in the size you’ll need for your packaging. If you need to change the size of the barcode art, do not shrink or enlarge it - it may not scan correctly. If you need to resize the barcode art, just re-create the barcode in the desired size.

When designing your barcode, it is important to allow adequate space for the barcode to be printed on the item to prevent errors at check out.

Looking to learn more about placing barcodes on your packaging? Check out GS1 US’s informative discussion on how to get your product manufactured or enroll in GS1 Package Measurement with GTIN Management Standard Certificate Course for a deeper dive into packaging and GS1 Standards.

With TEKLYNX label design software you can leverage built-in wizards for step-by-step creation of GS1 compliant labels. Create GS1-128, GS1 DataBar, GS1 DataMatrix barcodes, UPC barcodes, QR codes, and more.

Ready to start designing labels today? Buy barcode label design software online.

GS1 is a not-for-profit information standards organization. GS1 Standards are the most widely-used supply chain standards in the world. Founded in 1973 and based in Ewing, New Jersey, GS1 US administers the Universal Product Code (U.P.C.) barcode, as well as other information standards and data carriers. GS1 US collaborates with business and industry to encourage the adoption and use of GS1 Standards-based solutions that can help improve business processes.

There are thousands of uses for labels across industries, from product identification to shipping to marketing and more. Depending on the use of the label, size may vary from less than an inch to letter (or A4) size. At TEKLYNX, we see customers printing very small and very large labels, and everything in between.

READ MORE

Barcode symbologies differ by the type of data they hold and are encoded with. In this blog, we go over the categories of barcodes, the most common types of barcodes, and how to choose the best one for your labels.

READ MORE

Barcodes are the foundation for many industries and one of the most crucial parts of business operations, yet often overlooked. For operations to remain efficient and error-free, barcodes must be correct on every product or package. To keep your business and barcodes organized to prevent production downtime, chargebacks, and product recalls — avoid these eight common barcode mistakes.

READ MOREThe section on the importance of barcode size and quiet zones was particularly enlightening. It's fascinating to learn about the technical aspects of barcode design and how even small variations can impact readability.

Reply© Telif hakkı 2025 TEKLYNX CORPORATION SAS. Tüm Hakları Saklıdır.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.