Wybierz swoją lokalizację i język, aby korzystać z najlepiej przystosowanej strony internetowej

Wybierz swoją lokalizację i język, aby korzystać z najlepiej przystosowanej strony internetowej

A well-functioning labeling system is an important part of operational efficiency because it impacts nearly every part of your supply chain. An outdated labeling system can lead to misprints, noncompliance, and slow production. As your business grows, technology advances, internal processes change, regulations evolve, and customer demands increase, your labeling system has to keep up.

This blog covers how to evaluate your labeling system. We’ll dive into the questions to ask and how to determine if your labeling system has room for improvement.

Want to get right to it and see if your labeling system is holding you back? Request a free assessment with TEKLYNX.

When your labeling system is steady and reliable, it tends to be forgotten about. Even if it’s working now, sticking to the status quo isn’t always in your best interest when small improvements can have a big impact.

Auditing your labeling system regularly helps you make sure you’re compliant with changing regulations, your labeling system is supporting operational efficiency rather than hindering it, and you’re able to easily scale as your business grows.

With a well-functioning and up-to-date labeling system, you’ll see:

If no: You risk fines, recalls, and damaging your brand reputation.

If yes, but you have a hard time adapting to new regulations: You can make your labels more flexible and simplify updating them by brining label printing in house, designing label templates with variable data, and managing labels in one place.

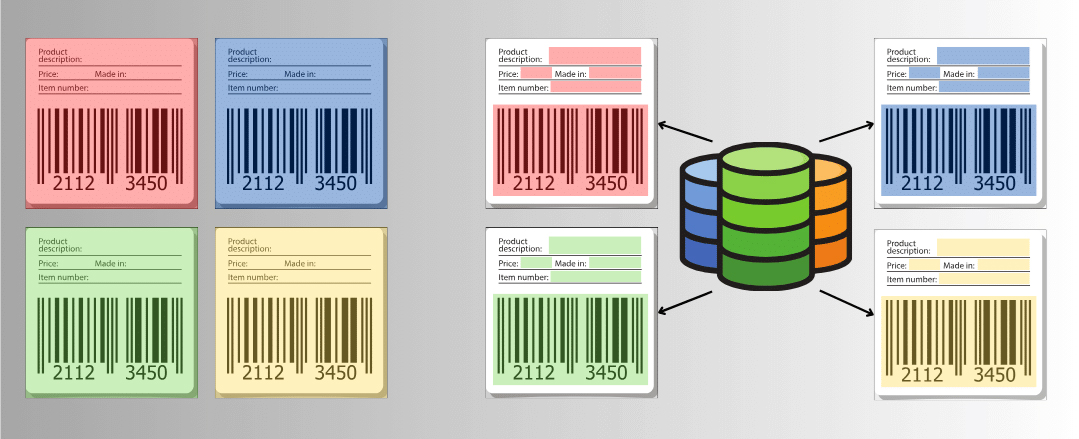

For example, instead of editing individual label files for every product variant within a product line (size, color, material, etc.) and potentially having outdated label files floating around or saved on individual workstations, you can design one label template with variable data for an entire product line and use cloud storage applications, like Google Drive and Microsoft OneDrive, to easily save them in a central location.

If yes: Similar to above, there's an opportunity to consolidate a bunch of static label files into a few label templates with variable data fields that are connected to a database to reduce the number of label files you need to manage or update.

LSI Industries eliminated 6,000 static label files by replacing them with database-driven templates, reducing ongoing label file maintenance by 80%.

If yes: There are ways to reduce human interaction if label misprints happen due to manual data entry or having too many clicks in your label printing process that leave room for error, like printing from your business system and automating your label printing.

Cavicchio Greenhouses faced challenges with label errors due to manual data entry. They integrated labeling with their Sage enterprise resource planning (ERP) system to print labels automatically and now have 100% labeling accuracy.

If no: Poor label quality or unreadable barcodes can disrupt internal operations and production, and the supply chain downstream. Your printer driver may be at fault:

With an embedded native printer driver, "What You See Is What You Get" (WYSIWYG) design increases overall quality and reduces reprints. Learn more in our white paper, TEKLYNX Label Printer Drivers: Don’t Compromise Quality.

If no: Growth and production will be limited by your labeling system’s capacity. By being able to easily add more printers or users and expand labeling to other areas of the business or more locations, you can reduce IT overhead and quickly respond to increased demand.

Lippert & Kinro scaled label printing from 1 to 239 printers to accommodate their growing customer and labor demands. "Our increasing number of customers were also requesting customization to their labels with items such as personalized UPC codes or serial numbers," said Jim Archambault, Lippert & Kinro’s project leader. "So, we set out to find a solution that gave us everything—standardization, time and cost savings, increased accuracy, ability to adapt quickly, and easier tracking. We were asking a lot."

If it takes too long and involves too many people or steps to print a label: There’s room to streamline your labeling process. Every minute your team spends manually printing labels is money wasted. Entering data, clicking through print screens, or fixing misprints adds up fast, especially in a high-volume environment like manufacturing.

MicroVention Inc. streamlined their entire labeling process, resulting in a 50% improvement in total production efficiency.

If you’re using multiple software brands, licenses, or versions: Consolidation and maintenance can simplify your tech stack and software management.

How do you determine if your labeling system has room for improvement? How do you look for hidden inefficiencies?

Once you've completed your labeling system audit and identified areas for improvement, it's time to act. Start by partnering with your labeling system provider to review your current setup. They can help you determine whether a version upgrade or a different software solution is recommended and if so, help you implement changes with as little disruption as possible. Collaborating with your provider is also an opportunity to learn about features or integrations to enhance your labeling system’s performance.

Next, you should prioritize the areas of improvement. You can focus on the smallest tasks that are easiest to fix or focus on the bigger issues that create risk of noncompliance or have the most impact on efficiency. For example, if misprints due to manual data entry are causing production delays or downtime, automating your label printing should be high on your list. If you struggle to keep up with evolving label regulations or industry standards, consolidating label files and centralizing label management should take priority.

Then create a clear action plan and align stakeholders from IT, operations, compliance, and quality assurance. Define your goals, assign responsibilities, and set realistic expectations for implementation—timelines, downtime, costs, etc. When it comes to costs, keep in mind the potential return on investment of improving your labeling system.

Lastly, define how you’ll monitor progress. Track key performance indicators (KPIs) like label error rate, misprint frequency, labeling-related recalls, and user satisfaction to assess the impact of your changes. Regularly reviewing these metrics will help fine-tune your labeling system over time and ensure it continues to meet your business needs.

Auditing your labeling system is about efficiency, ensuring compliance, and preparing for growth. Regular evaluations help you stay ahead of (or avoid) issues and continuously improve your labeling process.

As mentioned above, TEKLYNX can help! Reach out about our professional services—we can consult, design or convert labels, and validate your labeling process. We listen well and collaborate with companies to make them work better.

Casey Sciano is an Enterprise Executive at TEKLYNX. He uses his 15+ years of sales and technical experience and knowledge of the AIDC space to support enterprise label management clients. Casey strives to help clients "see the forest through the trees" by utilizing sound business strategies and sales techniques that impact the way they do business. When not working, he loves spending time with his dog Josie and cheering on the Brewers, Bucks, and Packers.

You wouldn’t wait years to go to the doctor for a check–up.

READ MORE

When you need to print a label, how long does it take to find the correct file, populate the correct data, and start the print job? If you’re not leveraging the power of variable data on smart label templates, it could take several minutes just to find the right label file!

READ MORE

Software system integration is a key tool used by businesses to enhance operations. Instead of each software application existing in its own silo, system integration allows separate applications to talk to each other. Integrating disjointed software solutions is commonly viewed as a challenge, but at TEKLYNX, we offer four main ways to integrate labeling systems with your existing technology stack.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Wszystkie prawa zastrzeżone.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.