Sélectionnez votre localisation et votre langue pour la meilleure expérience sur notre site internet

Sélectionnez votre localisation et votre langue pour la meilleure expérience sur notre site internet

Efficiency is all about doing more with less. When looking for opportunities to improve efficiency in your business, don’t forget to look at your barcode labeling system. If labeling has been a “set it and forget it” process, there’s a good chance there is room for improvement.

Improving connections between people, software, and systems enables you to achieve greater output with fewer resources. Better connections in your barcode labeling process can have a major impact on your bottom line and set your company up for success in the future.

Break free from manual labeling processes and experience an efficient barcode labeling system. This blog post will discuss how efficient barcode labeling is enabled by better connections in TEKLYNX labeling software.

Let’s start by defining what efficiency can look like in your barcode labeling system.

Designing labels is the very first step in the labeling process. Most companies already have something for label design, even if it’s pre-printed templates and a permanent marker. Some companies have thousands of label template files created over the years, taking up disk space and causing confusion about which file to use.

Efficient barcode label design starts with using a few well-designed templates to meet all your labeling needs. Templates should be based on label purpose and/or size. You don’t need to create a new template for each product, variation, or location. Instead, use variable data, which we’ll discuss in the next section!

Also consider how easy it is to create new label templates when they are needed. An efficient label design software should have a familiar interface, guide you with barcode generator wizards, and support a paperless label approval process.

Once your label templates are set up, make sure you have an efficient way to get correct data printed on the labels.

Inefficient label data could look like: handwritten data on a pre-printed label, users typing data in at print time, or users paging through data records to find the right one.

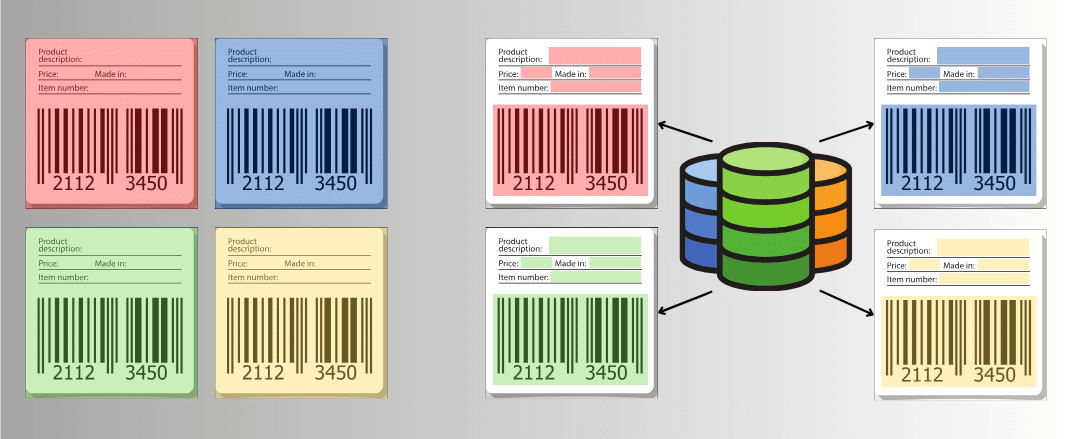

Efficient label data management takes out manual steps and uses software features to automatically get the correct data on the label. For example, connect the variable fields on your label template to database fields in your business system. Then use a unique key field, such as a product SKU, to automatically find the right record and populate the right data.

The last step is to efficiently print the right labels with the right data so they can be used in production. With efficient label design and data management in place, clicking “print” sounds pretty easy. But for large enterprises and high-volume label printing environments, opening an application to click “print” is another speed bump that slows down operations.

No matter your printing volume, consider the steps required to print a label. If users are opening an application, finding and opening a label template, populating any data manually, and clicking “print,” each of those steps takes time. Multiply this time across the many occurrences, production lines, locations, and workers, and it starts to add up.

An efficient label printing process removes these manual steps and automates label printing. The reduction in time and effort has a significant impact on companies’ productivity and efficiency.

Now that we’ve defined what efficiency can look like in a barcode labeling system, let’s dive into four specific and actionable ways you can achieve this with better connections.

For companies without a full business system application, data is often stored in a database or spreadsheet. This data can be connected to your label templates using label design software to eliminate the need for manual data entry by workers.

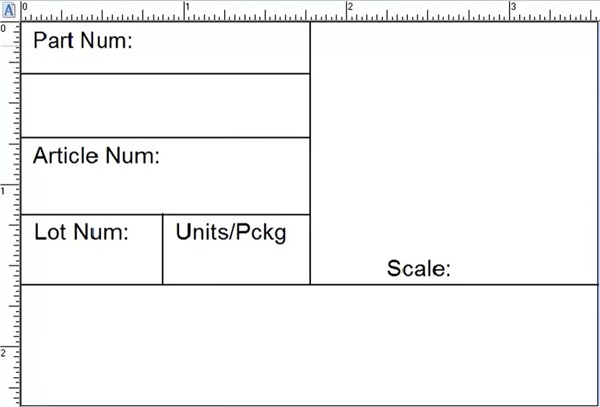

To set up a database-connected label template, first add the static text, lines, and shapes to the label template:

Then, use the database connection wizard to connect to any of the following local or cloud database types:

Once the database is connected, the fields will be available as data sources to be placed on the label in the appropriate position and format: text, barcode, or image.

After the database fields have been placed onto the label template, you can scroll through the database records and select which record(s) you wish to print at print time. Watch our full training webinar: Creating Database Connections with TEKLYNX Software.

Database connections make your barcode label data flow highly efficient by eliminating manual data entry and speeding up the printing process.

Label print forms are a very flexible way to add efficiency to your barcode label printing process. Forms can be used in virtually any labeling environment, whether you have connected databases or not.

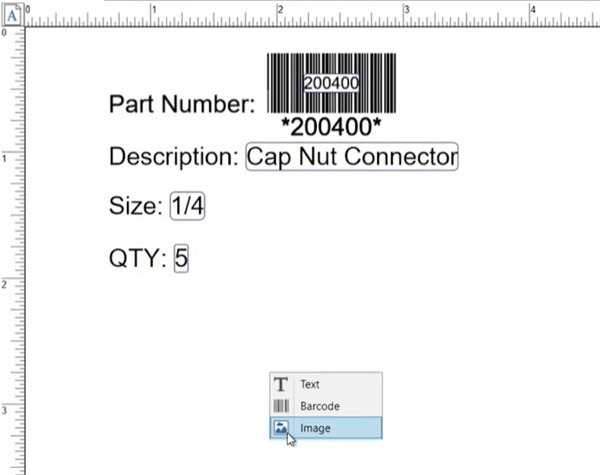

The simplest label print forms allow users to input data at print time without directly editing the label template. We call these “When Printed” fields. Of course, manual data entry leaves room for mistakes, so make sure to use data validation on the print form.

Data validation requires users to stick to a specified format for data entry. For example, only numbers may be used for a Quantity field, a Phone Number field must be in the format (###)-###-####, or a Lot Number field requires 10 alphanumeric characters. Presenting your print users with a data validated form makes it simpler and easier to print correct labels.

Label print forms can be combined with database connections by setting up a table lookup. A table lookup uses a Key Field in your database to select a database record for print. For example, the print user keys in a Product ID associated with the Widget 3000 10-pack. The Product ID is a unique value associated only with this product, making it an ideal Key Field. The table lookup uses the Product ID to automatically pull in all the correct label data for the Widget 3000 10-pack product label, and accurate labels are printed.

No matter how you’re printing labels today or where your label data comes from, label print forms are flexible enough to add efficiency to any labeling process. Watch our full training webinar: Creating Your Ideal Label Printing Process with Forms.

The methods described above form better connections between people and systems. Did you know you can also form better connections between your software and hardware by using native embedded printer drivers? Better software to hardware connections mean faster print speeds with more accurate results, leading to greater barcode labeling efficiency.

What is a printer driver? Software and printers speak two different “languages,” so they need a “translator,” known as a driver. Generic printer drivers are built to work with a variety of software and are not specialized for any particular program. Native printer drivers are specifically developed to work with a particular software and printer model, providing optimized communication.

TEKLYNX is the only barcode label software developer to invest in development of native printer drivers for thermal, thermal transfer, and inkjet label printers. We work closely with hundreds of printer manufacturers to develop and maintain native drivers for over 4,000 printer models. These native printer drivers allow you to adjust settings specific to the exact printer you’re using. TEKLYNX software and user settings are retained during version upgrades, saving you time.

When selecting your printer in TEKLYNX label design software, always look for the native printer driver option to optimize the communication to your printer and make barcode labeling more efficient.

Take a moment to picture your ideal label printing process: zero errors, instant print jobs, perfect quality, and no re-prints ever. In a perfect world, workers wouldn’t have to interact with a labeling system at all – the labels would simply print when and where they are needed. Most workers wouldn’t even realize there is a fully automated labeling system working behind the scenes.

The ultimate automated barcode labeling system is possible with TEKLYNX label print automation solutions. From the robust integration tools in CODESOFT + API, to our out-of-the-box automation tool, SENTINEL, to the hands-on TEKLYNX Software Development Kit (SDK), we have an automation tool that meets your needs. Let’s explore.

TEKLYNX enterprise-level label design software, CODESOFT, offers the ability to connect via API to automate printing. Ideal for companies that want to automate label printing to multiple non-networked printers and have in-house technical resources. The CODESOFT API includes .NET wrapper and ActiveX support for teams to integrate and automate label printing.

SENTINEL label print automation software uses a low-code integration method to process label print requests in a variety of ways. Some common input sources include:

The received data is then processed based on predetermined rules, correctly mapped onto your label template, and printed! Even the printer selection can be defined in the data input.

Created for software developers and solutions providers, the TEKLYNX SDK offers easy integration of label design and printing into existing software applications. Use the TEKLYNX SDK to add labeling functionality to ERP systems, WMS, MES, LIMS, or custom applications.

To learn more about TEKLYNX label printing automation solutions, watch our print automation webinar, Modern Approaches to Automating Label Printing: 3 Powerful Methods.

Interested in exploring our label automation solutions further? Request a consult with one of our labeling experts today!

REQUEST PRINT AUTOMATION CONSULT

Achieve greater business efficiency with an efficient barcode labeling system enabled by better connections. Whether you’re ready to implement a fully automation solution, or you want to add efficiency into your existing labeling process, TEKLYNX labeling experts are here to help. Request a free labeling efficiency consultation today!

Want more content on the topic of efficient barcode labeling? Watch our video and view our infographic!

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

As our world moves towards a digital transformation, automation is a crucial tool for a thriving business. By automating processes, companies can make their workflows faster and more efficient, enabling them to do more with less. This blog will go over how to automate your label printing and how TEKLYNX can help in providing solutions.

READ MORE

When it comes to your barcode labeling software solution, implementing lean labeling and continuous improvement principles to your labeling environment reduces waste in label printing and saves you money.

Dot Foods came to a point in their labeling process where they were looking to modernize their labeling operations and improve speed & accuracy.

READ MORE

Barcode labeling is a critical aspect of business operations to get your products to the right place at the right time. When it comes to improving operational efficiency, manufacturers regularly review key performance indicators like cycle time, on-time delivery, and customer return rate.

© Copyright 2025 TEKLYNX CORPORATION SAS. Tous les droits sont réservés.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.