Please select your location & language for the best website experience

What is a check digit? Simply put, a check digit is an extra number added to a barcode to help detect errors. Barcode check digits are calculated using algorithms during both barcode creation and scanning. If the scanned check digit matches the created check digit, the barcode was scanned correctly.

Check digits are foundational to barcode data integrity, validation, and quality. In this blog, we'll dive into what check digits are, how they work, and why they're important.

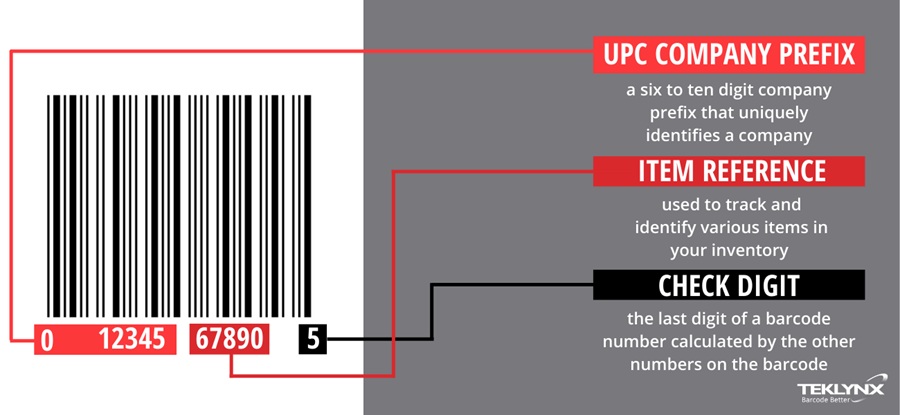

A check digit is a simple method of error detection with a lot of math behind it that ensures barcodes are scanned correctly. A barcode is made up of numbers, and the check digit is the last number in the barcode.

It's not part of the actual data of the barcode but is calculated using a complex equation. This means that different barcode values will generate different check digit values.

The check digit is calculated and written when the barcode is created. When the barcode is scanned, the scanner calculates the check digit using the same equation. If the result matches the check digit printed in the barcode, the barcode was scanned correctly. If it doesn't match, the scanner will display an error.

Most common types of one dimensional (1D) barcodes use check digits, including:

Two dimensional (2D) barcodes, such as QR codes and Data Matrix barcodes, don't use check digits because they have more complex methods of error detection.

Barcode accuracy is critical to every aspect of the supply chain, from manufacturing to shipping to retail. If a barcode is scanned incorrectly and the error isn’t detected, bad data enters supply chain information systems. This can cause a ripple effect of issues throughout the supply chain. For example, if a scanner in the receiving department misreads a "5" as an "8" in the product barcode, the wrong SKU would be logged into the inventory system. This would cause fulfillment issues, quality control failure, and delays. Additionally, manual investigation would be needed to trace the discrepancy and correct it.

Check digits are the first line of defense against barcode errors. They protect against common scanning mistakes and manual data entry errors. That’s why GS1 barcode standards require check digits.

Traditional barcodes are read in one dimension (left to right) with a laser scanner. The scanner emits a beam of light at the barcode. The black bars absorb the light, and the white spaces reflect the light back at the scanner. The scanner measures the reflected light to read the data encoded in the barcode. This analog process can be affected by dirt, damage, or anything that prevents the light from being accurately reflected into the scanner.

If dirt or damage causes the barcode scanner to read different data than what is actually encoded in the barcode, the scanner will calculate a different check digit than what is printed. The mismatch will cause the scanner to display an error.

If a barcode is damaged so badly that a scanner can't read it at all, it becomes necessary for the worker to manually enter the barcode data into the system. Check digits protect this process too.

Imagine the worker accidentally types "4" instead of "5" while entering the barcode number. The worker will enter the printed check digit last, but it won't match the check digit expected by the system. The error will be identified and flagged for correction.

GS1 is the global not-for-profit organization that defines and maintains barcode standards that are used across industries. GS1 barcodes make it possible for barcodes created by a company in one country to be read by another company around the world.

GS1 requires check digits on all fixed-length numeric GS1 Identification Keys such as Global Trade Item Number (GTIN), Global Location Number (GLN), and Serial Shipping Container Code (SSCC).

Companies in retail, transportation & logistics, healthcare, and food & beverage industries all benefit from GS1 compliance, including the use of check digits.

Check digits are calculated using math formulas called algorithms. When the barcode is created using barcode software, the check digit is automatically calculated and added to the end of the barcode. When the barcode is scanned, the scanner instantly calculates the check digit and compares it to the scanned check digit. If it matches, the barcode is successfully scanned.

One popular check digit algorithm is the Modulo 10 algorithm. Computers can process this algorithm in milliseconds, but it takes a human a little longer to calculate.

Take a UPC barcode with the digits 012345678905. Here’s a simplified version of how its check digit (the last number, 5) is calculated using the common Modulo 10 algorithm:

For a visual representation, take a look at GS1's webpage.

If a scanner misread one of the digits, for example, 012245678905, it would calculate the check digit as 6. The scan would result in an error because 6 does not match the last digit of the printed barcode: 5.

Luckily, we don't need to manually calculate check digits. GS1 provides a check digit calculator on their website, and barcode printing software such as LABELVIEW automatically calculates check digits for barcodes.

The best way to print barcodes with accurate check digits is to use barcode label printing software. LABELVIEW barcode label software includes barcode generator wizards that automatically calculate and print barcode check digits.

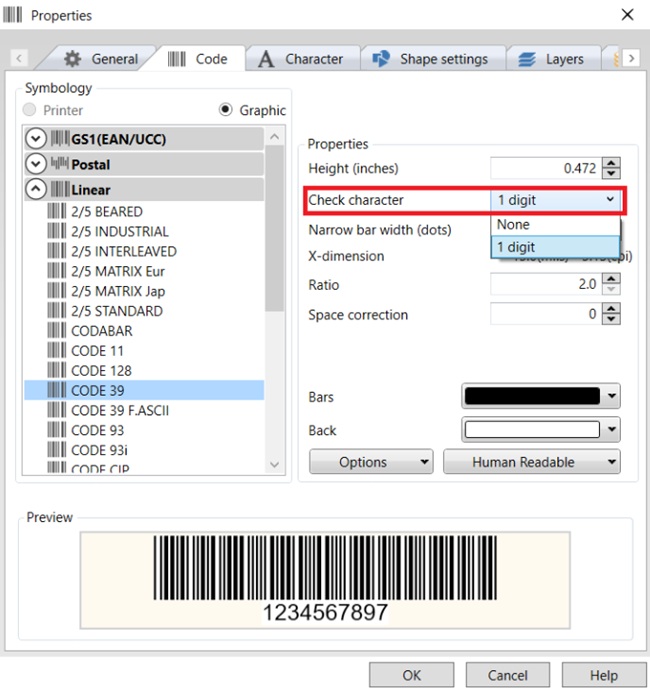

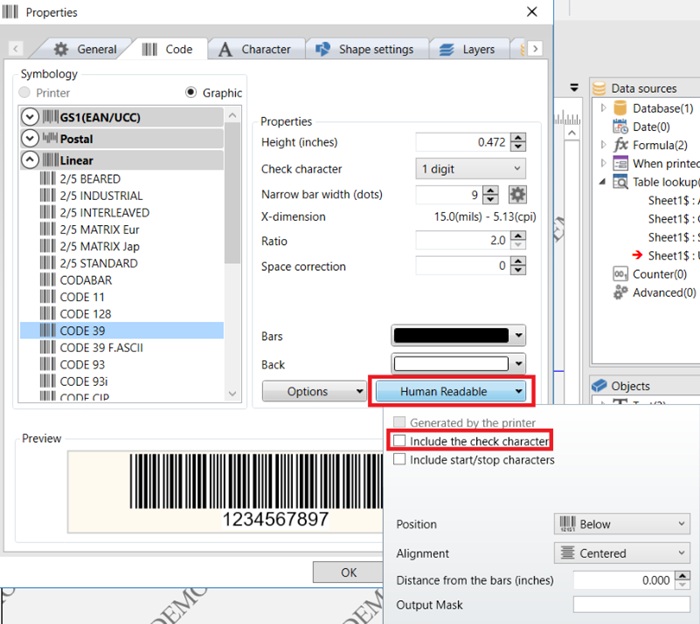

In LABELVIEW, you can configure the properties of each barcode, including the check digit.

If workers at your company manually enter barcode data into a system instead of scanning it, look for ways to improve this process.

Let’s recap what we've learned about check digits. Key takeaways include:

Companies use barcode label software like LABELVIEW because it easily and accurately prints barcodes with check digits. LABELVIEW can generate over 100 types of barcodes, supports GS1 compliance, and can print to all common label printers. Download a free 30-day trial to find out how easy it can be to protect your supply chain data.

Ready to buy? Buy LABELVIEW.

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

Barcodes are the backbone of supply chain operations. But what does that mean for you and your business? In this blog we explain everything there is to know about barcodes and why they matter.

READ MORE

Barcodes are the foundation for many industries and one of the most crucial parts of business operations, yet often overlooked. For operations to remain efficient and error-free, barcodes must be correct on every product or package. To keep your business and barcodes organized to prevent production downtime, chargebacks, and product recalls — avoid these eight common barcode mistakes.

READ MORE

Barcodes are not just simple lines and numbers; they are powerful tools that facilitate seamless inventory management, enhance supply chain operations, and enable businesses to operate with remarkable efficiency. In this blog post, we will delve into the technicality behind barcodes, explore different types of barcodes, explain how barcodes work, discuss their diverse applications, and highlight why they are indispensable to the supply chain and businesses.

Barcode symbologies differ by the type of data they hold and are encoded with. In this blog, we go over the categories of barcodes, the most common types of barcodes, and how to choose the best one for your labels.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. All Rights Reserved.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.