โปรดเลือกตำแหน่งที่ตั้งและภาษาของคุณเพื่อรับประสบการณ์เว็บไซต์ที่ดีที่สุด

In the fast-paced manufacturing world, efficiency is key to staying competitive and meeting customer demands. One thing often overlooked is the role of labeling in enhancing manufacturing efficiency. Accurate, fast, and compliant labeling can streamline operations, reduce errors, and help products move smoothly through the supply chain.

Using the right enterprise labeling software can make all the difference, especially for IT and operations leaders in manufacturing. In 2024, the best enterprise labeling software solutions boost efficiency through label print automation and quality control, allowing you to focus on other critical tasks.

Check out our eBook, The Power of Enterprise Label Management Software, to read all the ways enterprise labeling software can benefit your business.

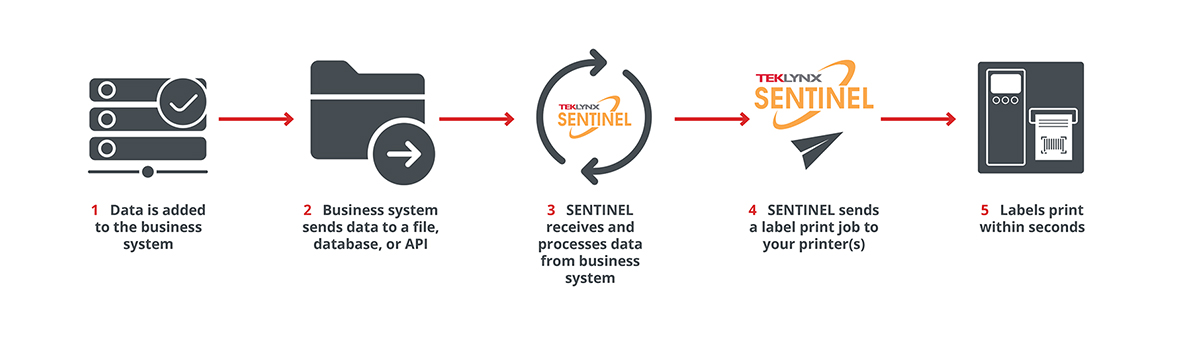

One of the most sought-after features of enterprise labeling software is automatic label printing. For example, print automation software decodes any type of data and automatically maps it to text, barcodes, or images on a label template. This is particularly valuable for manufacturing environments where data from systems like SAP, Oracle, and other ERP platforms need to be seamlessly integrated into the labeling process.

Optimized print speed is another factor. An enhanced print engine ensures all print jobs initiate quickly, even during startup. This means less downtime and more efficient production runs. Additionally, print automation software sends files by email—such as labels, pick lists, or advanced shipping notices—simultaneously with a print request, further streamlines operations. This reduces the need for manual touchpoints, minimizing the chances of errors and ensuring all necessary documentation accompanies the physical products.

Quality control is particularly important in labeling. It directly impacts product traceability, compliance with industry standards, and sustainability or waste reduction. Label security and traceability software includes features to ensure label quality and control. For example, user permissions can be set to control who designs, approves, and prints labels, for a consistent and secure labeling process.

The label approval workflow is another important part of label quality control. With features like a label comparator, users can view proposed label edits directly from the approval screen, making it easier to review and approve changes. This helps ensure only approved labels make it into production, maintaining high standards of accuracy and compliance. Additionally, reprinted and test labels can automatically have a watermark added to prevent unauthorized labels from entering production.

TaylorMade Golf, headquartered in California, is a leading manufacturer of high-performance golf equipment. Before implementing TEKLYNX, TaylorMade faced significant challenges in their labeling process. “Our biggest issue was the lack of flexibility in label data sources and the restrictions it imposed on our business processes,” said Rafal Janus, Senior Manager of Solutions Development at TaylorMade. Plus, changes to labels required involving a third party and any significant changes cost approximately $8,000.

By choosing SENTINEL print automation software, TaylorMade was able to manage their labeling process internally, eliminating the need for third-party software maintenance. This change allowed them to edit label templates without external assistance, reducing their total equipment cost by 50% and showing a positive return on investment.

Dot Foods, the largest food industry redistributor in North America, needed a new labeling software to support their labeling needs and provide technical support across their 14 distribution centers. With SENTINEL, Dot Foods maintained a high-availability environment and achieved reliability in their labeling processes across all distribution centers.

The integration with internal applications and portable printers created even more efficiency in their labeling environment. “TEKLYNX has made it easier with a much better tool set. Better label designer, better integration; it all works together now,” said Troy Schenk, Warehouse Systems Manager at Dot Foods.

Top Clean Injection, the subsidiary of Top Clean Packaging, specializes in the co-design and production of medical devices. They leverage over 1,000 different labels for various uses, including products, samples, and shipping, many of which need to comply with international medical device shipping labeling standards.

With label security and traceability software, LABEL ARCHIVE, Top Clean Injection has a completely compliant labeling environment in a highly regulated industry. “Traceability in labeling is an extremely important step for product conformity,” said Elisabeth Tavard, Validation Manager at Top Clean Packaging. “With LABEL ARCHIVE, there’s no doubt who created or approved it. Our paperless label approval process is much more professional, and we maintain so much more control from creation, to review, to approval, to print.”

The best enterprise labeling software solutions require little to no manual maintenance once installed and configured. Regular software version updates provide customer-centric enhancements, improved security, pre-loaded native label printer drivers, and bug fixes, so the software remains reliable and compatible with other technologies.

TEKLYNX offers expert guidance and troubleshooting from the customer support team and enterprise engineers. This level of support ensures any issues are promptly addressed, minimizing downtime, and keeping your labeling operations running smoothly.

Label print automation and quality control are key benefits of using enterprise labeling software. These functionalities not only boost efficiency, but also ensure accuracy and compliance, allowing you to focus on other critical tasks within your manufacturing operations. Choosing TEKLYNX as your solution provider means reliable, efficient, and comprehensive support and software that meets your needs.

If you're looking to improve your labeling processes and boost efficiency, TEKLYNX is here to help. Contact us or request a demo to discover how our enterprise labeling software can meet your specific requirements and elevate your manufacturing operations.

Casey Sciano is an Enterprise Executive at TEKLYNX. He uses his 15+ years of sales and technical experience and knowledge of the AIDC space to support enterprise label management clients. Casey strives to help clients "see the forest through the trees" by utilizing sound business strategies and sales techniques that impact the way they do business. When not working, he loves spending time with his dog Josie and cheering on the Brewers, Bucks, and Packers.

In 2024, the best barcode labeling software meets the needs of modern manufacturers. Savvy IT directors want the right balance of cloud and on-premises technology. Above all, users are choosing software providers that put their customers first. TEKLYNX 2024 products bring new cloud features, expanded customization options, and are supported by an award-winning customer support team with global locations.

READ MORE

Software system integration is a key tool used by businesses to enhance operations. Instead of each software application existing in its own silo, system integration allows separate applications to talk to each other. Integrating disjointed software solutions is commonly viewed as a challenge, but at TEKLYNX, we offer four main ways to integrate labeling systems with your existing technology stack.

READ MORE

How can companies best manage compliance labeling? A reliable enterprise labeling system enables smart label templates, an audit-ready label approval process, software validation, and barcode verification. In this blog we’ll explore how these enterprise labeling features help companies manage compliance labeling.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. สงวนลิขสิทธิ์

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.