सर्वश्रेष्ठ वेबसाइट अनुभव के लिए कृपया अपने स्थान और भाषा का चयन करें

The future of cannabis labeling centers around the efficiencies companies can create to overcome the business challenges of today: timely manual processes prone to human error, disjointed data sources, state-by-state packaging and labeling requirements until cannabis is federally regulated, and inflexible systems hindering expansion.

Download eBook: Labeling for the Cannabis Industry

As cannabis companies are maturing and investing in technology, we’re getting more questions about ways to streamline labeling operations and future-proof labeling environments. Plus, as we see headlines about companies paying $100,000 for mislabeled cannabis products due to human error, finding ways to automate and ensure label quality is critical to the health of the industry.

Below are a few of the common questions we receive around cannabis labeling efficiency and how TEKLYNX can help provide efficient solutions to overcome labeling pain points today and set vertically integrated cannabis companies up for future success.

Yes. Any data you’re collecting by hand or manually entering to print labels or report to regulatory authorities can be collected much more efficiently with automatic identification and data capture (AIDC) or barcode labeling technology.

Yes. TEKLYNX barcode labeling software integrates with Metrc, a seed-to-sale traceability and compliance management solution used by regulatory bodies for the oversight of the cannabis industry. Metrc’s open application programming interface (API) was designed to interface with cannabis systems to minimize manual inputting and uploading tasks. TEKLYNX software removes the potential for error when gathering data that needs to be reported from seed to sale as Metrc requires it.

Printing custom labels is an important part of cannabis operations. Metrc-sourced tags may not provide enough identifiable information for internal processes and certain states have additional labeling requirements. TEKLYNX can help fill the gap.

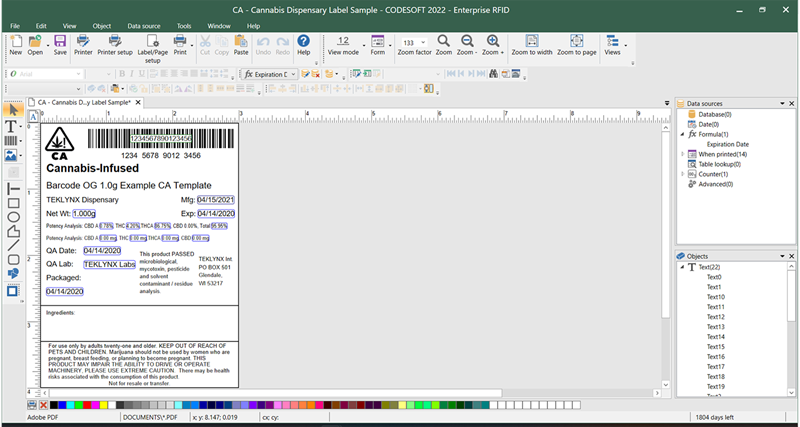

While implementing TEKLYNX software will not miraculously make you compliant, the combination of our state-specific cannabis label templates, powerful software features that enforce labeling accuracy, and the published cannabis labeling requirements for your state will make it very easy to get you there.

Until cannabis is federally regulated, companies have to meet state-specific labeling requirements, which can feel overwhelming. We know you already have a lot to figure out, so we took the first step in designing compliant cannabis labels off your plate. State-specific cannabis label templates are available in CODESOFT label design software, so you can easily pull in data and print cannabis labels quickly.

Familiarize yourself with your state’s cannabis packaging and labeling requirements for labeling dos and don’ts and lean on your barcode label design software provider to help you along the way. TEKLYNX knows success needs support, so we work around the clock to help the world’s greatest brands work better. Regardless of whether you are considering TEKLYNX for the first time or you have been a long-time customer, we are here for you.

For cannabis companies with many locations or plans to expand, a small IT staff, or desire to minimize associated IT effort and resources, managing labeling can become a handful. Network licensing and browser-based label printing are two ways to consolidate labeling if your environment expands across multiple facilities.

Network licensing allow you to manage labeling software users at multiple locations from one central IT office. If your locations are all on the same network, you can use one network license for all locations. If your locations are not on the same network, you can still leverage separate network licenses to manage the software for multiple users at each location.

Browser-based label printing can significantly simplify labeling across all your locations. Local software installations are eliminated, and authorized users log into a webpage to print labels from anywhere. A browser-based label printing system makes labeling at multiple locations easy by centrally managing seed-to-sale labeling and integrating with your company’s existing cannabis ERP or other business system. Smart label templates are built to pull in data directly from these systems, standardizing the labels and eliminating errors from manual data entry.

Pro tip: Suppliers can also be given access to the secure browser-based label printing interface, allowing them to print the most up-to-date version of a required label.

Whatever cannabis labeling regulation or labeling process challenge your business faces, TEKLYNX solutions help growers, processors, packagers, and retailers efficiently create, print, and manage compliant cannabis barcode labels for plants, lab samples, glass jars, vape cartridges, pre-roll tubes, and more.

Get in touch with TEKLYNX and we’ll connect you with one of our many experts to assess your current barcode labeling environment and needs in just 15 minutes – it’s free and with zero commitment. Let’s find ways to make your life easier with the help of barcode labeling technology.

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

As growers, distributors, and dispensaries know extremely well, cannabis is quickly becoming a big-money industry with huge opportunities to scale up and grow your business.

READ MORE

At any step in the cannabis supply chain, your labeling system should allow for full control and traceability, from seed to sale.

READ MORE

If you encountered a labeling error today, would you be able to confidently pinpoint how and why it took place? Unfortunately, for many companies, the answer is “no.” Many companies have a label design and approval process that is informal, manual, and prone to mistakes.

So, how can you reduce the risk of labeling errors to near zero? You can set your company up for success by implementing an automated label audit trail. A label audit trail is a reliable, consistent way of documenting changes made to label designs. Maintaining an accurate label audit trail reduces the risk of labeling errors and helps pinpoint the cause if they happen.

READ MORE© कॉपीराइट 2025 TEKLYNX CORPORATION SAS. सर्वाधिकार सुरक्षित।

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.